In September Kovis foundry was presented at the 57th International Foundry conference in Portorož. The company prepared a presentation entitled « How To Eliminate Gas Defects in Gray Casting«. Learn more about it in a short summary.

Abstract:

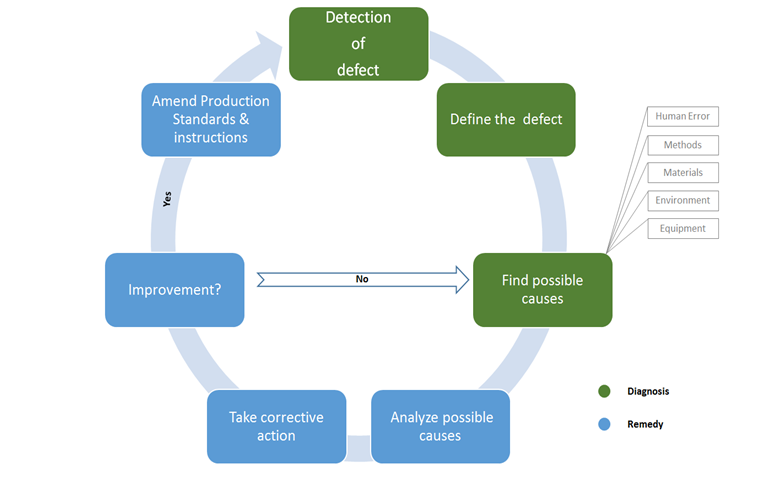

Grey Iron gas defect must be defined properly, in order to have a correct investigation. The most important phases during investigation are first the detection of the defect, followed by the definition and finally finding the possible cause of the defect. Based on an accurate, quick diagnoses we can build a solid foundation to analyse and review all related factors and parameters in order to help us in taking the appropriate corrective action. Putting the casting on a trial test will confirm to us if the action we have taken is the correct one. It is not necessary for the selected action to eliminate the defect, but it is important to see a noticeable improvement. (Pinholes) is Spherical shape cavity (sometimes elongated or pear shaped) The internal surface in most cases is smooth and shiny. The cavities are small in size(1-2mm), separated in form leaving a trace always oriented perpendicular to the surface. (Fissures) the elongated cavities are usually irregularly rounded with a tail similar to a comma ((,)). The internal cavity surface is usually dark, lined with a shiny graphite film which contains slag or manganese sulfide inclusion or combination of these. The dendrites penetrat into the cavity. It is bigger in size (2-9mm), stretching a few millimetres perpendicularly into the casting and along the surface. Both could be visible on surface or after machining tolerance. Tending to occur in heavy castings where first solidification happened. Several actions had been taken to reduce the percent of local scrap due to gas defects:

(a) Reduce the Manganese content, when we have the sulphur content on minimum level, because the amount of manganese required to neutralize sulphur is (1.7 x S wt%), In this case we could have extra residual Manganese in melt which can increase the risk of dispersed type of defects:

(b) Avoid high aluminium wt% as it increases the H-related defects.

(c) Work on adding elements who has the positive impact on graphite nucleation and on tying up nitrogen, like Sr,Ba & Zr.

(d) Improve feeding system and pouring time which helps us to reduce too high pouring temperatures.

(e) Improve venting technology using simulation and create there prints on mold.

(f) Reduce the difference in temperature between mold and core sand.

(g) Reduce using rusty raw materials to supply the cupola furnace.

(h) Use clean type of inoculation with minimum Ca content wt% as the last react with oxygen and create CaO solid films.

Following the right procedure helps us to understand the complexity of cast iron production, and allow us to find some better solutions in order to reduce the risk of gas related defects.